Cold Crucible Induction Melting

Catalogs:

Overview

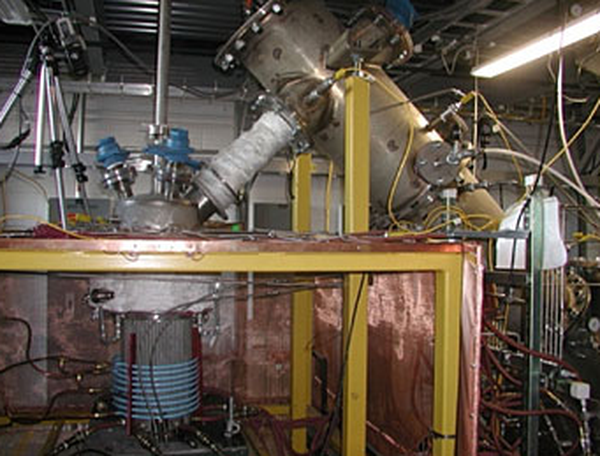

An induction coil surrounds a melter shell constructed of electrically-isolated water-cooled metal tubing. When an electric current passes through the coil, it inductively heats an electrically conductive susceptor inside the melter. The susceptor heats starter glass frit until it becomes molten, when it is also electrically conductive and inductively heated. New feed is heated by, and melts into, the molten glass. Water-cooling of the crucible tubes freezes a thin layer, or shell, to form inside the melter wall. Thus, the melt can be heated to at least 3,000 degrees C while maintaining the melt in a solid containment shell that isolates the melter from the melt and at the same time, protecting the melt. The induction heating and cold crucible design eliminates the need for electrodes that directly contact the molten glass and refractory used to contain the melt.

-

No tags applied

Developed by

Orano (f.n.a. Areva)